OSMOS WiM+D® - Weigh In Motion & Deformation

The OSMOS WiM+D® tool will revolutionize how you manage your bridges. Backed by our experience in infrastructure monitoring, we focused on developing a unique, automated solution that combines weigh-in-motion techniques with the analysis of structural deformation. The resulting OSMOS WiM+D® is a major innovation in the field of bridge monitoring, as it does much more than simply studying traffic over your structure. Today, thanks to structural health monitoring, we are able to determine the impact of your bridge's operations on its state of structural health, so that you can improve its management and guarantee user safety.

OSMOS WiM+D®: Weigh-in-motion reinvented

WHY USE OSMOS WIM+D®?

- FOR INCREASED SAFETY OF HIGHWAY USERS.

- FOR OPTIMIZED MAINTENANCE TO HIGHWAY OPERATORS.

- Access to your bridge's state of health;

- Maintenance of your structure in working condition and prevention of shutdowns;

- Real-time monitoring of usage, traffic and their impact on the structure;

- Identification and classification of passing trucks using cameras;

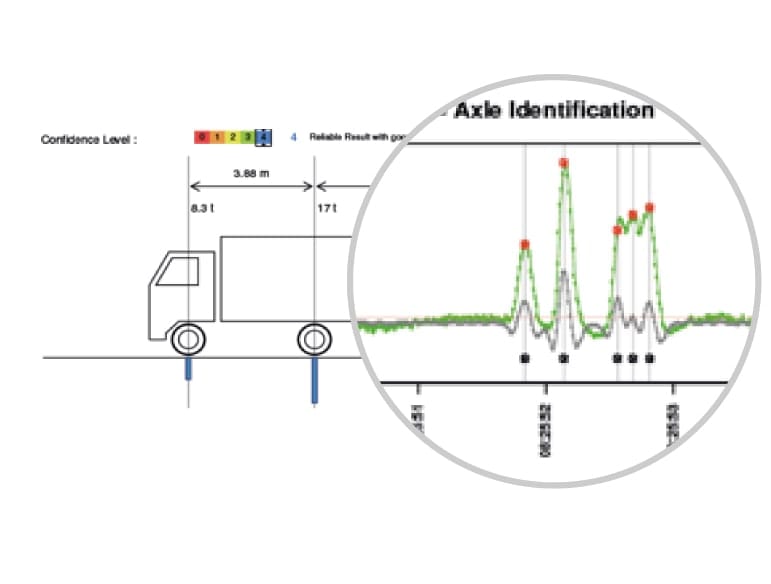

- Precision detection and weighing of each axle;

- Alerts in the event of overload and/or structural anomalies;

- Optimized maintenance scheduling and budget control;

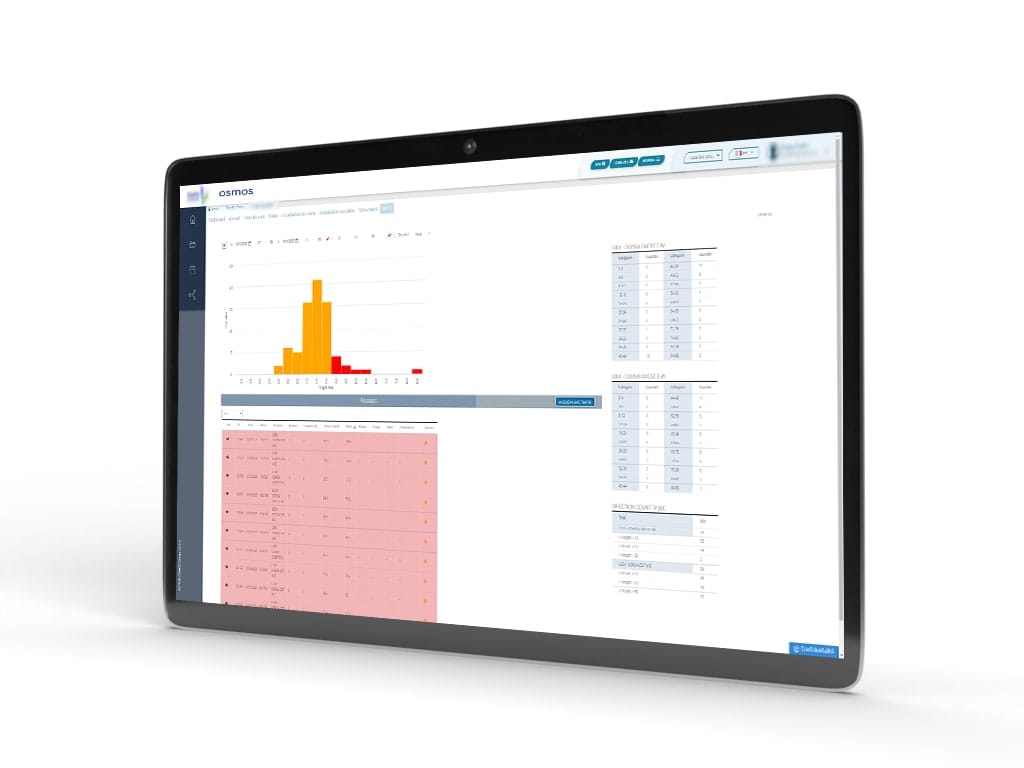

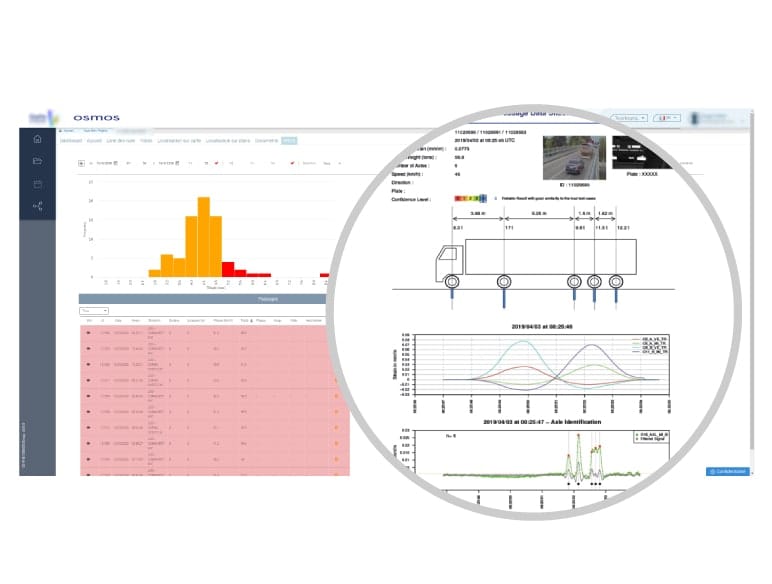

- Simplified structural asset management via SAFE suite, our unique integrated software platform;

- Extremely easy installation for activation in record time.

DETECTION, WEIGHING AND COUNTING OF OVERLOADED AXLES AND TRUCKS

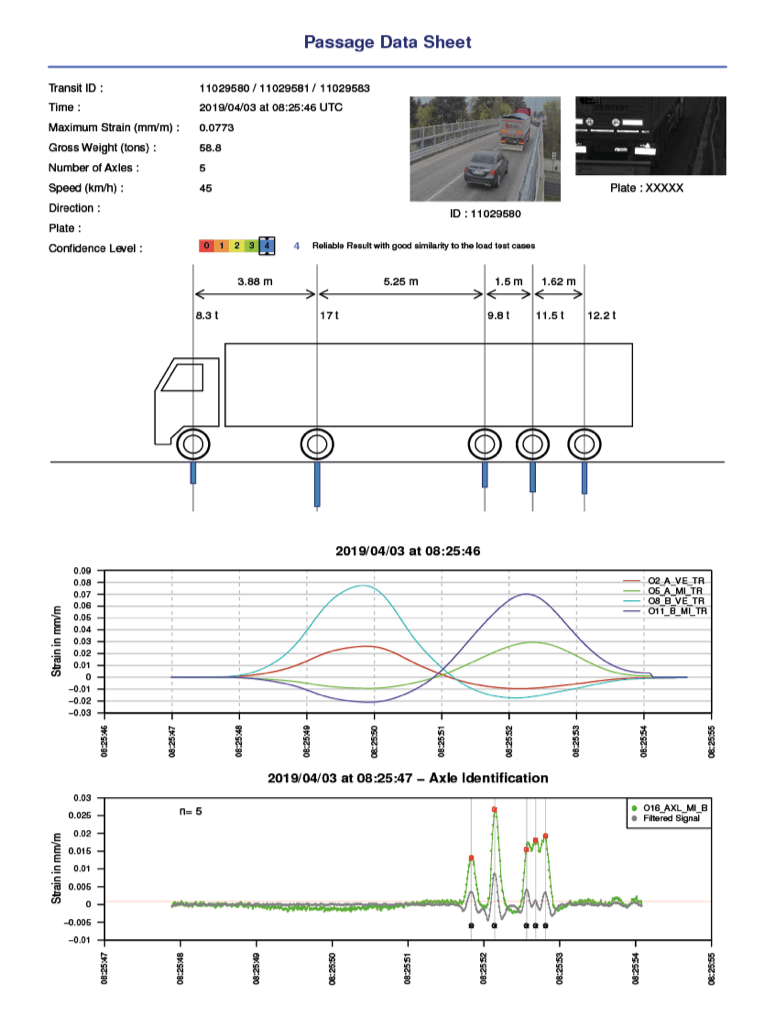

By arranging our fiber-optics sensors (OSMOS Optical Strands) under the deck of the structure, without damaging it, we can obtain key information thanks to dynamic signatures recorded every time a heavy vehicle passes over it.

The installed Optical Strands act as both weight sensors and measurement sensors for structural deformation. That dual purpose yields information like the heavy vehicle’s speed, length, direction, number of axles, weight distribution by axle and total weight, as well as the maximum strain caused by it passing over the structure. Heavy vehicles are automatically classified by weight and by direction, which can then be viewed via the online interface, SAFE Works.

ANALYSIS OF STRUCTURAL DEFORMATIONS

The algorithm developed by our teams goes beyond classic weigh-in-motion methods. The OSMOS WiM+D mathematical module counts the heavy vehicles crossing over the bridge and assesses their weight, based on an analysis of the dynamic measurements detected and recorded by the Optical Strands.

The deformation measurements recorded for each passing truck are used to verify the deck’s normal structural behavior under moving loads: actual level of deformation, continuity, height of neutral axis, blockages on supports, etc.

REAL-TIME VIDEO AND TRUCK IDENTIFICATION VIA CAMERAS

To minimize fraudulent behavior, OSMOS WiM+D allows you to reinforce the monitoring of vehicles traveling over your bridge, thanks to video surveillance cameras installed on-site and linked to our data-capture systems. Each truck is identified by its license plate and its timestamped passage. That information can be viewed in real time on our online interface, SAFE Works, which also gives you access to all of the passing heavy vehicles, categorized by weight and by direction.

OSMOS SAFE WiM+D®

OSMOS WiM+D® is our new weigh-in-motion solution that will revolutionize how you manage your bridges. This mathematical module, available on SAFE Works, records the history of heavy vehicle passages that have passed through your bridge and are likely to have an impact on its condition. You have access to a classification by weight and direction of passage, as well as details of each vehicle passage. The OSMOS WiM+D® solution can also be combined with real-time cameras installed on site to identify each heavy vehicle.

Convoys detection

- Recording of a dynamic signature for each passage of a heavy vehicle

- Estimation of the weight of heavy vehicles and measurement of the structural deformations induced by their passage

- Counting and classification by weight and direction of passage

- Evaluation of the speed of each vehicle

Weighing of each axle

- Detection of the truck configuration

- Counting the number of axles by heavy vehicles

- Estimation of the load for each axle

- Estimation of truck length